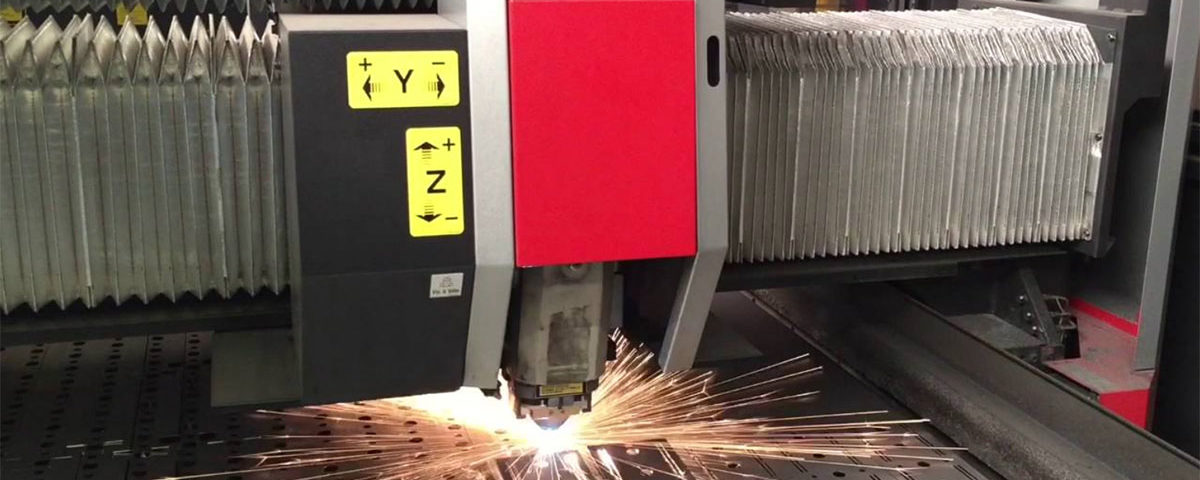

The 3kw 6kw and 9kw fiber engines incorporate amada s ensis technology that optimizes the laser mode and beam parameter product bpp based on the material thickness being processed.

Amada fiber optic laser.

This technology helps achieve process range expansion p r e by having the ability to process brass cop per and titanium materials that can be difficult to process with a co2 laser.

The 3kw 6kw and 9kw lcg aj series was developed with amada s proven fiber laser technology.

Ensis 3015aj is equipped with amada s own developed fiber laser.

The ensis series achieves high speed cutting in thin material a key capability of fiber technology and the ability to process thick plate efficiently.

Their advanced motion and.

The 3kw 6kw and 9kw lcg aj series was developed with amada s proven fiber laser technology.

Matt wood marketing senior product manager of amada europe hq introduced the amada flc 3015 aj fiber laser cutting machine in krakow.

Energy saving v lot production wide range fiber laser machine with process range expansion.

This technology helps achieve process range expansion p r e by having the ability to process brass copper and titanium materials that can be difficult to process with a co 2 laser.

The premium amada laser benefits listed above allow for reduced lead times and processing costs which in turn reduces overall customer costs.

With an innovative motion system and advanced structural design the lcg aj series represents an optimal balance.

2000w new city ny view listing.

The 2kw lcg aj was developed with amada s proven fiber laser technology.

The laser technology in amada laser cutting machines allows for high cutting speeds and the flexibility to process a wide range of materials like aluminum steel copper and brass resulting in process range expansion p r e.

With an innovative motion system and advanced structural design the lcg aj series represents an optimal balance.

This technology helps achieve process range expansion p r e by having the ability to process brass copper and titanium materials that can be difficult to process with a co 2 laser.

Make tempco manufacturing company your first choice for high precision fiber optic laser cut metal parts.