The graphite fins are bonded to the base with thermally conductive epoxy keeping the heat sink.

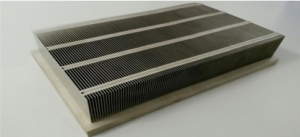

Aluminum graphite heat sink.

But the real advantage of graphite is its weight it weighs just 70 percent of the weight of aluminum.

Our products are also impressive thanks to their low coefficients of thermal expansion and low density.

Yet the literature is void of true comparison of these materials against copper and aluminum.

Get contact details address of companies manufacturing and supplying aluminum heat sink aluminium heat sinks across india.

Another material that s gaining popularity with heat sink producers is a natural graphite composite material.

Find here aluminum heat sink aluminium heat sinks manufacturers suppliers exporters in india.

The graphite heat sink s thermal performance was only 12 lower than aluminum at low flow rates.

This material is being used today as a fin material in combination with an aluminum or copper base to make hybrid heatsinks.

This behavior is evident in the table below and when comparing the different heat sink materials.

A wide variety of graphite heat sink options are available to you such as bending cutting and punching.

Heat sinks made of aluminium graphite the thermal properties and ability to manufacture components with a wide variety of different geometries make aluminium graphite an outstanding material for conducting heat.

To address the issue of graphite foam as a viable material for heat sinks a series of tests were conducted to compare thermal performance of geometrically identical heat sinks table 1 made of copper aluminum and graphite foam table 2.

Aluminum heat sink 150 x 74 x10 mm 5 9 x 2 91 x 0 39 inch blue heatsinks module cooler fin heat board cooling for amplifier transistor semiconductor devices 4 6 out of 5 stars 6 9 99 9.

This leads to an improvement in the overall reliability of the electronic system.

Parts made of aluminium graphite effectively remove heat from hot spots and reduce mechanical tension within the assemblies.

Schunk aluminium graphite products can be used in various markets including transportation industry and communications technology.

It s not as conductive as copper but it s close with a thermal conductivity of 370 w mk.